Multi-Deck Screen

Highest capacity. Perfect for grain and agriculture. This machine features BM&M's highest capacity while maintaining a compact footprint.

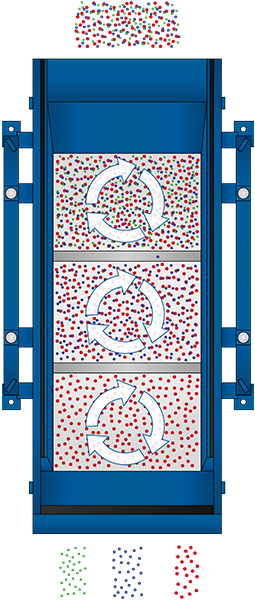

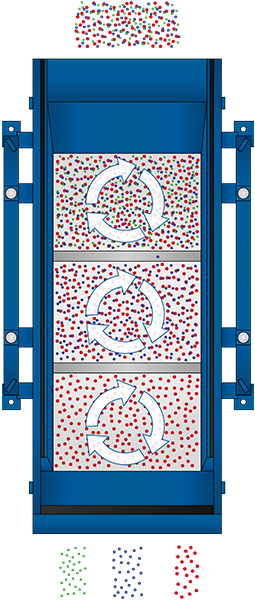

The Multi-Deck Screen is a stacked configuration screener that offers BM&M’s highest capacity screener in the most compact footprint possible and is ideal for agricultural applications. The consistent motion across the screen and the high speed combines to make this multi-deck gyratory screener extremely efficient.

This machine is dynamically balanced, which allows it to be installed virtually anywhere in a plant. This flexibility results in the lowest possible installation costs. Our BM&M Multi-Deck Screen is ideal for large agricultural applications while being simple to install, operate, and maintain.

Features

BM&M Gyratory Motion

The unique technology developed by BM&M creates an unbeatable combination of motion and speed that generates higher throughputs and greater efficiencies. There are 3 core elements that work together to deliver these results.

- Centering the drive in the middle of the machine to generate the a gyratory motion over the entire screen surface.

- The eccentric weight drive assembly is lubicated for life. The unique static shaft design provides torsional stiffness ensuring long trouble-free service reducing ongoing machine maintenance costs.

- Increasing speed results in higher screening energy being applied to the material, eliminating blinding while also increasing throughput.

Product Options

Hanger Sling Assembly

Additional Support Option available to ensure no damage to your equipment in the event of double hanger failures.

Centralized Lubrication System

System designed to allow for greasing of the U-Joints by an operator without requiring a machine shut down period.

Over Travel Sensor

To detect when equipment is traveling outside the programmed range of motion and implement machine shutdown.

Upgraded Material for Wear Parts

A wide range of material upgrades can be provided to ensure your common wear components have a longer life span.

Zero Speed Switch

To detect when the machine has its regular operation disrupted or has reached a zero speed state.

Open Bottom Construction

Elimination of fines pan to eradicate blinding of fines material that can freeze or bond to metal in changing weather conditions.

Installation

BM&M Supplied Stand

The multi-deck gyratory screener can be floor-mounted using a support stand designed for the specific screener machine.

Existing Structure

Because the machine suspension system has low to no vibration, the multi-deck gyratory screener can be mounted directly to a structural steel framework using custom-length hangers assemblies.

Manual Request

Need an original manual to know what parts are needed for your BM&M equipment? Request one here and we’ll advise if it’s available.

* Required Field